Artificial intelligence ERP: How AI can help ERPs?

What is Artificial Intelligence ERP System?

Today Artificial Intelligence and Machine Learning in ERP Systems have changed the Current Business Models. Many business models are simplified and manual efforts have been taken out. This increased the demand for newer ways of displaying and consuming the data points. Many industry verticals are changing their practices and adapting to newer technologies.

For example: Banking, Retails, eCommerce, Medical practitioners etc are seeing great result in adopting AI and ML into their business models. How an AI with ERP systems can change the Industry that’s not changed from its original way of thinking from 1980’s? An interesting question and this lead to many new terminologies like IOT, AI, ML etc. We will also discuss few use cases of Artificial Intelligence in ERP systems and IOT in Manufacturing communities.

Artificial Intelligence ERP and Machine Learning tools can help an Enterprise Resource Planning software with the below areas of business.

- Supply chain management with business process automation

- Remove mundane and Repetitive Tasks

- Human resources management and Compensation management

- Acts as a virtual assistants to manage and alerts users.

- Inventory management and real-time insights into Demand and Supply.

- Helps in Resource allocation for the business. Improve logistic planning etc.

- Improved efficiency with manufacturing process and avoid non-productive tasks. Monitor production costs and alerts when it’s needed.

- Auto invoice processing as the Finished Products are ready.

- Demand forecasting with predictive analytics

- Customer relationship management

Artificial Intelligence ERP / AI-enabled ERP software with these process automation could save millions of dollars to companies. Improved operational efficiencies with avoidance of routine tasks can improve customer service and customer experiencetoo. This makes a happy employees in the company whose productive can improve.

Google, YouTube, Amazon, Facebook etc uses the Artificial intelligence and machine learning heavily in their search or product recommendation engines to predict a person’s preference, behavior and his interest areas. These tools are used to predict customer behavior, his purchase patterns, what type of ads he wants to see etc. That means, if a person logged into Internet means, his data is no more private and machines will start checking what he is doing etc. Scary situation.

How Artificial Intelligence (AI) and Machine Learning are changing ERP systems? How an AI ERP Systems is created?

How Business is impacted by Artificial Intelligence (AI) and Machine Learning? How an Artificial Intelligence can influence ERP Systems and Manufacturing industry?

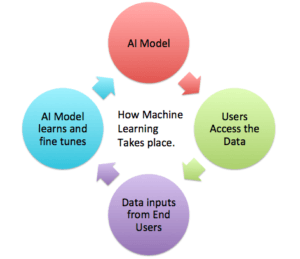

What is important is for AI and ML is the data inputs and availability of repeated data to study and analysis. This is where an ERP can be helpful to store the transactions data and make it available for AI and ML tools.

Let’s understand Artificial Intelligence ERP’s impact with an example of Enterprise Resource planning tool (ERP).

Before we get into the details of how technology innovations are changing the ERP and Business owner’s needs, let’s see the current problems that are faced by an SME Business Owner.

It is an open secret that ERP helps many organisations to streamline their Invoice processing, Production reporting with Inventory controls etc. ERP can extend your Business to your Sales persons, Customers, Vendors etc. The tools has the capability to integrate entire business operations into one place.

But many business owners are afraid to go for an ERP due to its high maintenance cost, Hardware and Server costs, it’s License cost etc. An off-the shelf ERP is very expensive with consultants fees, Implementation charges etc. So a small SME can’t afford to buy ERP software. Due to this reason Business Owner compromised himself with basic accounting software that helps to fulfil the Taxes and Compliance needs and rest is managed by Excel document or kept the data manually.

What about the Mid and Large Enterprises? Are they happy with their ERP and how it works?

I have few questions for them to answer. You can also send an answer to sales@actouch.com

Is there any single company or Enterprises that uses 100% of their one ERP Product features?

Answer to this question is very LESS as the large enterprises depends on multiple ERPs to meet their different business needs and manage Distributors etc. So this leads to chaos as the same data has to entered or moved across different ERPs of different formats.

How many business owners plan and forecast the expected cost of Hardware and Software in the next 3 years?

Most of the Business owners don’t even know that they have to upgrade their ERP Hardware as the new version of ERP is released. Their ERP vendor hides this information at the time of sales. Traditionally the SME Business owners depends on the Hardware vendors to suggest RIGHT SOFTWARE. So there is a bias in selection of right ERP for business.

How big is the IT Team of your company? Do you know that an AI ERP Systems would change the industry behaviour?

AI ERP Systems will collect the production patterns and could arrive at the future production plans based on the past forecast and available data. Is the above problem only for Mid and Large Enterprises? No, the same you can see in the Small and Medium Enterprises too.

One of the major reason is, Artificial Intelligence ERP Systems is necessary for all Small and Large Enterprises who does SIMILAR type of activities. It doesn’t depend on HOW many, but it depends on what and all to be done.

Artificial Intelligence ERP: How about SMEs? How Best AI for ERP works?

They use multiple software like separate tools for Accounting, Inventory software etc. They use CRMs that’s been helping them when they started business. Problem for them is SMEs are afraid to change whats working. So Artificial Intelligence in ERP looks interesting, but chances to replace them is low due to cost factors or don’t know what to do.

Artificial Intelligence ERP: What is happening now? Who own customer success?

There are multiple factors.

- In the last 5 years, the cost of Hardware, Network and Internet has reduced dramatically. Thanks to Amazon Web Services (AWS) and Google Cloud to provide a cheap and secure Cloud Environment.

- The SAP’s or Oracle’s of the world are struggling to sell their Old Software that is of mammoth size and huge for a SME or an enterprise that’s focusing on what they need? Now a days SAP has come with Cloud based solution and smaller version to cater to SMEs. However the Implementation and maintenance costs are still high.

- Who owns Customer Success? Earlier days, a large ERP vendor is happy to sell the User Licenses and his partner would be happy to collect Implementation fees, customisation fees etc. If Customer has issues with the Core ERP solutions, then there is no one to help them. Vendor will blame on ERP Vendor, and ERP Vendor will never respond, as he is not responsible for the implementation. In summary the project fails with lot of money spent and who owns “Customer Success”? There are many large ERP implementation are failed due to a single factor or missing decision like “Who owns customer success?” Read our article here

The new generation entrepreneurs or second-generation businesspersons don’t want to sit at one place as they have realised that to do business they should meet people and do more sales.

So factors that are weighed to select an ERP are different from what it was earlier. Today every CEO thinks on how to reduce the cost of the ERP / Software, how to reduce the unnecessary expenses like Hardware, networking, IT Admins and teams etc.

This is where the new generation of tools are solving many Business Problems. Recent development and an easy access to new technology and integrate them with Old and new software makes a difference.

A new initiative of Digital transformation, Data security and ensuring to catch-up the large companies for the business, the Business Owners have decided to try ERP Software for their business.

So how the future of ERP is redefined? How the old ERP companies are reinventing themselves and changing their price plans.

Create Business value with IOT for Manufacturing industry

As part of ERP sales, we interact with many industry vertical leaders. Our experience with Manufacturing, Trading & Distributors, SOHOs, Service companies etc. help us to understand their inherent problems and how it can be solved with help of IOT.

Manufacturing sector is one of the industries that could exploit an opportunity to scale themselves by using AI and ML features. However this alone is not possible, as we need to provide the data inputs from CNC or any other Machines to Data analysis points. This is handled with the help of IOT (Internet of Things) objects.

While the advantages are many, the cost to benefit has to be calculated. I have identified few use cases based on our experiences.

Internet of things (IOT) and Artificial Intelligence ERP

IOT helps to connect many manufacturing process and machines activities to ERP and store the data. As the production reporting happens, these data are stored directly in Cloud ERP. This is building interoperability between business process and machines etc. So back office data is synced with Stores and Shop floor data. In Real-time the shop floor or production data is fed into ERP and helps Stores person to send the demand request to Vendor based on shortage of items. A total integration based on the actionable parameters.

Now we are talking about IIOT – “Industrial Internet of Things”. This is being supported by few Artificial Intelligence ERPs, IOT frameworks and software to connect and define interoperability.

Few use cases of Artificial intelligence ERP and IOT for Manufacturing Industry:

1. Production Planning

One of the major challenges in this team is the frequent changes in the demand and supply. How can you pass the information to CNC Machine as the demand changes? How to ensure that the data is synchronized between the Planning and Production department? How to inform Purchase department to stop the PO or Inform Stores department on what to do?

2. Demand generation and alerts to Vendors on the quality of products

How do you measure and control the quality of products / raw materials and these issues comes into picture during production work only? Post-production the challenge is to transfer this information back to Vendor, so that his vendor ratings are reduced. Stores department receives the materials against the Vendor documents and it can be traced back to the document, batch number etc.

3. Machine production reporting process

During components production time, the quantity reporting is done at the end of the day or at the end of shift. This leads to problem where the immediate decisions are not taken for the production team and leads to more wastage and increase in the cost of production etc.

4. Machine breakdown / Maintenance

Alerts with production planning and change in scheduling. Lets assume that one of the important machines that help to manage the critical production is down and the information should be made available to the service engineer immediately to take actions. Based on the message, he can begin his activities.

Scanning and MRI machines are the best example for this.

Artificial intelligence ERP and Machine Learning

Many of us use Siri in iPhone to make calls, or do some other work. Amazon’s Alexa and Google Assistant is another great example of AI and how it can be integrated with normal life of humans.

The same can be extended to Manufacturing industry with Shop floor / Quality is connected to the Production reporting with Stock updates. The data analysis could be immediate and helps senior management to take decisions on production, its repetitive issues and what caused the errors.

As the ERP understands and learns by its own data points, it leads to a situation that could prevent the future problems that could arise because of a Supplier, his materials and its grade, the Size of materials etc. could lead to decision making process.

Another interesting example is, based on the previous Production Data, Sales numbers, Finished goods costing an intelligent ERP could arrive at the Cost of production should be. It will also calculate if a Unit Sales price is decreased by USD 1 and how the product cost could be decided, what is the kind of target market stake we could achieve etc.

Technology is changing rapidly, but our old manufacturing process is not changed. So the new entrants can take benefits with technology. This is where an Artificial Intelligence ERP software could bring more value to business.

This is the power of AI ERP and its cloud Data

Fix your product DEMO NOW with our ERP Expert. It’s FREE.

|