Best Discrete Manufacturing ERP Software

Manufacturing industry is a very large segment of business and they follow multiple business and process to suit their business model to delivery. So you need a Best Manufacturing ERP that suits the discrete Manufacturing, its process and provides the necessary controls too.

Discrete Manufacturing focusses on the Individual components manufacturing that follows step by step manufacturing process to convert the same from Raw Materials to finished products by using Bills of Materials. It could be the Finishing operations or Assembly operations to combine few subassembly to manufacture a Main Components / Finished Goods.

Worldwide, majority of manufacturing sector is of discrete manufacturers type. They follow 100% discrete manufacturing processes and don’t mix it with Process manufacturing process. In case they need any Process manufacturing capability, they start a separate company and become a Process Manufacturers.

What is Discrete Manufacturing?

Few examples to understand more on the Discrete Manufacturing Products are

- Injection Molding.

- Small and large Machines and its assemblies

- Project based items, its assembly and onsite installation.

- Electronics Parts manufactures and its assembly.

- Automobile Components

- Tractors and farm equipment parts and Assembly

- OEM Components like TV, Washing Machines, Fridges etc.

- Forging, Extrusion etc.

To make a Finished goods it requires multiple Subassemblies or same part that transforms from Raw materials to Finished goods based on the business needs and process. One of the major things that happens, when a company decides to produce a specific set of items is, it changes its production layouts, workshops, Structure of departments and how they co-ordinate each others etc.

Every decision and the work is more towards increasing productivity, efficiency and improvement in cycle time from Order to Delivery.

This is where ACTouch manufacturing ERP helps companies.

Many of our customers in Automobile segments, Large machine manufacturers, Injection Molding and Tools, Electronic Assembly, Switches and controls, Hot and Cold Forging, Extrusion, Hand tool manufacturers etc use this method. So ACTouch is designed as a “Discrete Manufacturing ERP” to handle all these types of scenario, complexity etc.

Discrete Manufacturing Industries

Some Discrete Manufacturing Industries are Automobile, Electronic Equipment, Apparel, Communication Equipment, Electrical Equipment, Medical Devices etc. For these industries you need a vertical specific ERPs like “Discrete Manufacturing ERP” that focused 100% on these process only to produce discrete products.

Few Discrete manufacturing software helps here. But they fail when you have Mixed-Mode Manufacturing comes into.So it is always better to adapt to an Enterprise Resource Planning like ACTouch Cloud ERP Software.

Our Customers

|  | |||

| ||||

|  |  |

How can you increase productivity while using ACTouch ERP for your business operations?

ACTouch Manufacturing ERP is a software that is designed for small business owners who are looking to make their operations more efficient. One way to increase productivity while using ACTouch ERP is by taking advantage of the time-saving features it offers.

ACTouch ERP has a few features that can help you save time and streamline your day-to-day operations. For example, the system allows you to customise your dashboard with data that are tailored to your preferences, meaning you will always have easy access to the information that is most important to you.

Additionally, ACTouch ERP gives you options for generating reports on demand so there is no need to waste time waiting for one report at a time. It also allows users the ability group data in order to analyze trends and spot opportunities more quickly.

ACTouch is a Cloud Enterprise Resource Planning (ERP) Software for Small and Midsize (SMB) Discrete Manufacturers and Distributors.

Many manufacturing units like Automobile Components, Injection Molding, Large Machine manufacturers, Forging (Hand tools) or heavy forging components manufacturers follow a process that’s called Discrete Manufacturing. Means that make one component of a Finished goods at one stage at a time. So these products are unique and identifiable properly and are different from process based components like Oil or Chemicals etc.

Discrete manufacturers produce items that are either consumed by the consumer directly or its part of some other Finished Goods. Today industry is depending on these units to supply the majority of the components.

The processes deployed here is not a continuous in nature or it could be a Unit wise production where the one Machine output is immediately inputted to another machine and end of the day, the Supervisor is reporting only the Outcome of the Finished Goods. Each process can be individually started or stopped and can be run at varying production rates. The final product may be produced out of single or multiple inputs or operations.

ACTouch, Manufacturing ERP software specially designed for Discrete Manufacturing Industry with best features.

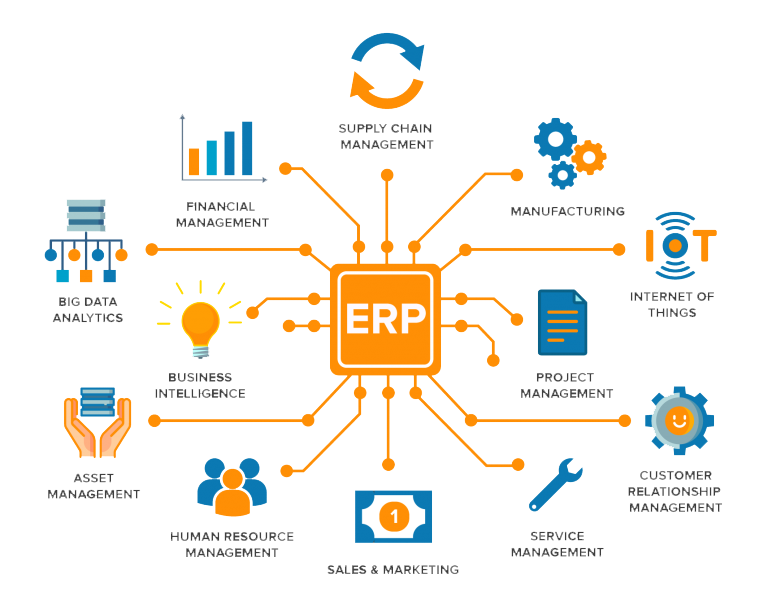

Few features are.

- Sales Order Processing – end to end Order Processing with Import and Export features.

- Purchase Order Processing – Procurement cycle that’s integrated with Inventory and Supplier Payments.

- Inventory management and Inventory Control

- Financial management with regulatory requirements

- Taxation and compliances.

- Manufacturing Process with built in controls for production process with real-time visibility – You can handle In-house Production, subcontracting and Customer Job-work orders etc.

- Planning and Forecasting – A good ERP to manage the Demand and Supply of materials.

- Costing module to control FG and RM costs.

- Supply chain management with 100% business processes mapping capability

- Production planning and production schedules with an Advanced planning features.

- Customer relationship management

- Quality Control and Quality management

- Tracking of production costs and product costs.

- Manage Product Lifecycle Management

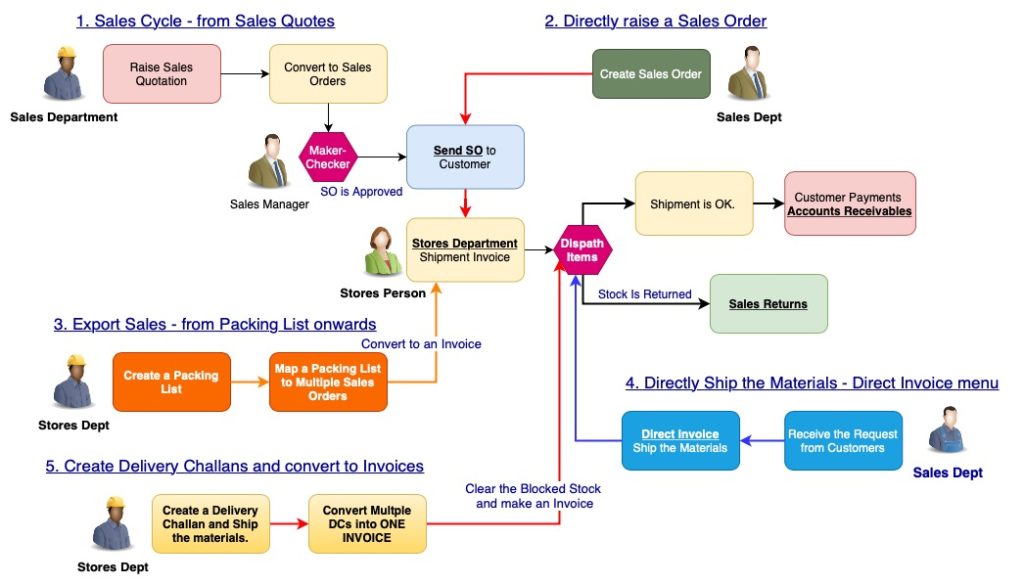

Do you know how many methods are in ACTouch ERP to make a Sales Invoice?

Check here…

in ACTouch ERP, you can make an Invoice / Shipment of materials by having 4 to 5 types of data inputs and follow the process. End Result is same. However depending on your business policy follow the methods.

- Sales Quotation -> Sales Order -> Invoice / Shipment

- Sales Order -> Invoice / Shipment

- Direct Invoice (Here there is no Sales Order to refer)

- For Export Sales – Make a Packing List -> Map to Multiple Sales Order -> Make ONE invoice.

- Make Delivery Challans -> Invoices (Multiple DC can be combined to ONE Invoice.

ACTouch ERP’s features and benefits

| Bill of Materials (BOM) 1. Manage the materials required to make a Finished goods. 2. Find the accurate Product Costing with labor, Machine costs. 3. Manage By-product and rejection handling | Work Order 1. Convert WorkOrder from a confirmed Sales Order. 2. Track your Customer Order 3. Manage the Routings, Work Center, Scrap and rejection handling. 4. Helps to manage multiple level production with accurate planning. | Sub Contracting 1. Manage the subcontracting operation with Outward Delivery Challan 2. Receive the FG from Inward DC. Track 100% materials sent to Contractor and how much he produced at one place. |

| Sub Contracting 1. Manage the subcontracting operation with Outward Delivery Challan 2. Receive the FG from Inward DC. 3. Track 100% materials sent to Contractor and how much he produced at one place. | Material Requirements Planning (MRP) 1. Manage your product Demand and supply 2. Helps to generate Purchase Indents and Work Orders 3. Helps to balance the items with Re-Order level stocks. | Complete Integrated Solution ACTouch is a completely integrated Solution for Manufacturers, Jobworkers, Large Machine Manufacturers etc. |

| Sales and Purchase Order Processing 1. Create Sales order and convert to a WO to track the productions 2. Manage the Invoices, Job work Invoices. 3. Manage Purchase orders, Receive Materials etc | Inventory Control 1. Accurate Costing of Raw Materials to Finished Goods 2. Manage Stocks of Batch, Non Batch and MUOM items. 3. Helps to manage Physical inventory and stocks. | Quality Management. 1. Manage all your Quality testings Reports the quality cases at Stock Receipts, FG Receipt etc. 2. Generate the reports to see the Quality issues, if any. |

How ACTouch Manufacturing ERP can help you?

Few industries that we work 100% perfectly.

- Automobile Industry, Tractors and Farm Equipment Manufacturers

- Manufacturing ERP for Plastic Products Manufacturers

- Chemical and Process Industry Manufacturers

- Manufacturing ERP for Electronics Manufacturers

- Manufacturing ERP for Farm Equipment and Automotive Manufacturers

- Manufacturing ERP for Industrial Products

- Manufacturing ERP for Medical Devices Manufacturers

- Manufacturing ERP for Forging and Sheet Metal Fabrication Software

- Manufacturing ERP for Import Export Business

- Manufacturing ERP Jobwork and Subcontracting Operations