Best Production Planning Software: Cloud Planning Software Designed for Manufacturers

ACTouch, Production Planning Software is a comprehensive Enterprise Resource Planning (ERP) Software that provides a transformation for Manufacturing companies from a conventional software. Cloud ERP Features solution that enables companies to compete at the prevailing market. A better direction of your manufacturing processes transform the Supply Chain to achieve Production plan with Finance. Summary, we help to integrate your Manufacturing Eco-system with your offline and online presence with Subcontractors, Customers etc through our Production Planning Software.

ACTouch, an enterprise resource planning system helps to convert raw materials to finished products in real time with planning for right production process and right utilisation of production capacity.

With a product features like capacity planning, Business owners can able to take an informed decisions like what’s the production schedules to follow, on which machine to complete, what resource allocation to be done, what are the on-time delivery we can achieve etc. What is important is the knowing of production costs and resource management to follow to increase resource utilization and reduce costs. Even sending the parts to subcontract work is also part of this plan.

Some of the key benefits of production planning software is

- Integrated supply chain management

- Production planning tools and run production planning process

- Ability to plan for raw materials to Finished products

- Production management with production processes and production schedules

- Production lines / Production Bays maximise utilisation.

- Inventory management tools with Product Costing mechanisms.

- Purchase order releases and procurement plants.

- Advanced manufacturing production scheduling with Machine Capacity planning etc.

- Material requirement planning

- Entire manufacturing process with control on operational costs etc

When a business focusses more on customer satisfaction as a primary objective, then they should go for a production management software with a production scheduling process too.

Best Manufacturing Production Planning Software for Small and Medium Business in India

ACTouch, a Production Planning Software enables users to access Enterprise Resource Planning (ERP) software over the web. Cloud ERP generally has substantially lower upfront costs, because the month leases computing tools instead of purchased and maintained in your premises. Cloud ERP gives companies access with their business-critical software.

ACTouch, a Production Planning Software is designed for Manufacturing Companies like yours. We support different types of manufacturing process like

What is important, our ERP strength is in managing Inventory Costing with Stocks across multiple locations, Import and Export Business, Product Landing Costing, Sub Contractor Management etc. We are also an expert on ABC (Activity Based Costing) to arrive at Product Costing. Manufacturing Business is changing today with new trends like AI and ML etc.

ACTouch Manufacturing ERP is 100% fit for Small and Medium Industries. Check here.

Few of our happy Customers with our Production Planning Software

Selection of a good ERP is difficult. Why don’t you see ACTouch ERP Demo and then decide on Production Planning Software or a manufacturing planning software?

Your ERP Data is 100% Safe & Secure on Our Amazon Server.

Why Many Manufacturing Companies are happy with ACTouch, a Manufacturing ERP Software?

OEM Manufacturer

“ACTouch.com helped us to save 50% of our efforts in managing Inventory, sending and receiving etc. Because of this, now we started our second company due to these time savings. I am happy that I did the right choice”

Manjunath Naik. Director, IM SafteySolutions.

Trader and Distributor

“This is the best team and the Software support I’ve received. They always helps us quickly, in a very professional and easy to understand way. Today our three businesses are using ACTouch.com”

Mukund B.S. CEO, ReNewIT, Bangalore

Calibration Vendor

“ACTouch Team developed our Calibration process on Cloud with the necessary customisation. They helped us to move into Digitisation of our manual process. For this digitisation, we received award from GE Healthcare”.

Vijay Kumar, Director, TransCal Bangalore

Good Manufacturing ERP Software in India designed for Manufacturing Companies.

Simplify your Work, Improve Process and Reduce Cost with ACTouch cloud Manufacturing ERP Software

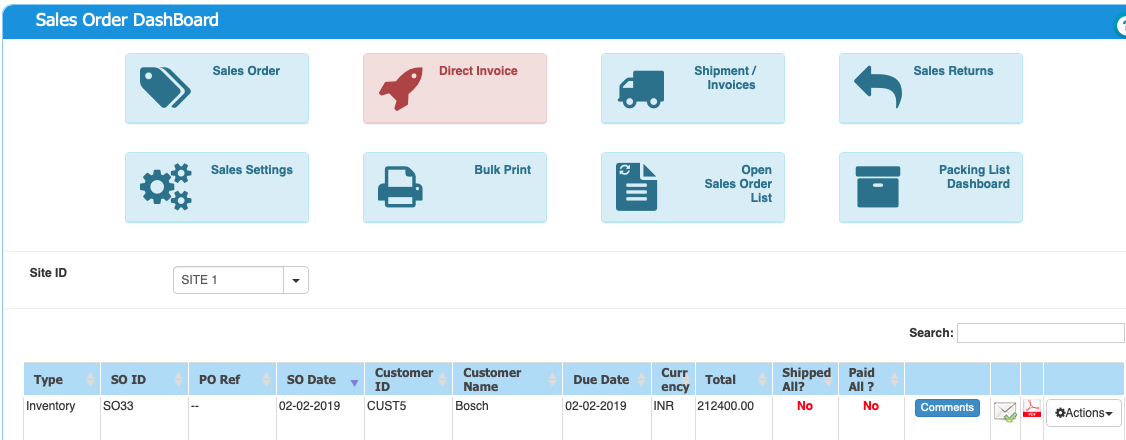

Sales Order Processing with Production Planning Software and Supply Chain

Many managers ask questions like

- What is Sales order and its process in Manufacturing ERP Software?

- What is the difference between Sales Order and Invoice?

- How to do an Export Invoice and collect money?

We are trying to address all these questions here with an explanation on how a Production Planning Software can help Manufacturing Companies?

Sales Order Processing

ACTouch.com has the following modules that helps and streamlines your business

- Sales Quotation – Helps to send Quotes

- Sales Order – Inventory, Services, Multi Currencies.

- Convert SO to Invoice or generate Export Invoice

- Handle effective Sales Returns

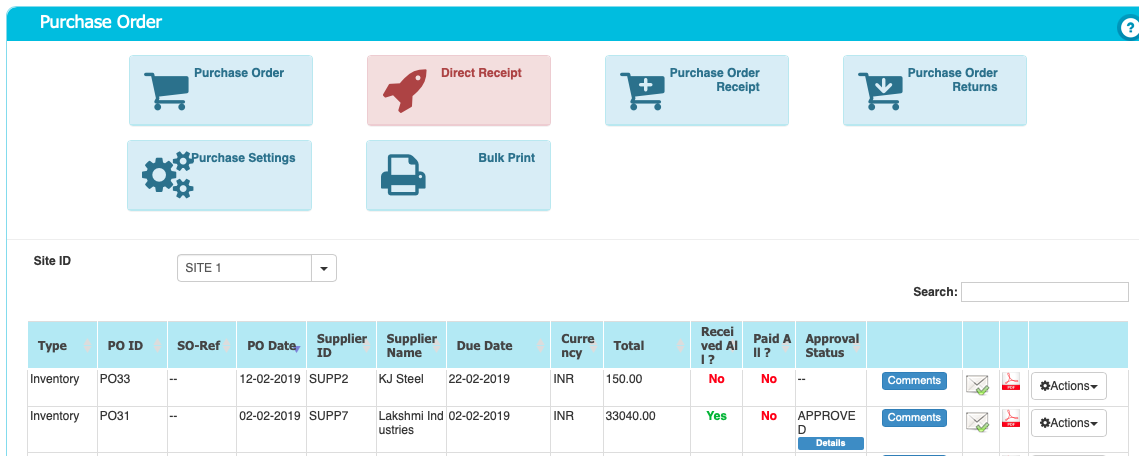

Purchase Order Processing integrated with Production Planning Software.

Many managers ask questions like

- What is Purchase order and how it helps?

- What is the difference between Purchase Orders and Goods Receipts?

- How to do an Import Goods receipts?

We are trying to address all these questions here with an explanation.

Purchase Order processing

With ACTouhc.com, you can create the following documents

- Purchase order for Inventory or Import

- Receive the materials and it updates Inventory

- Purchase Returns and its helps to manage Inventory

Its a powerful tool for Purchase Managers

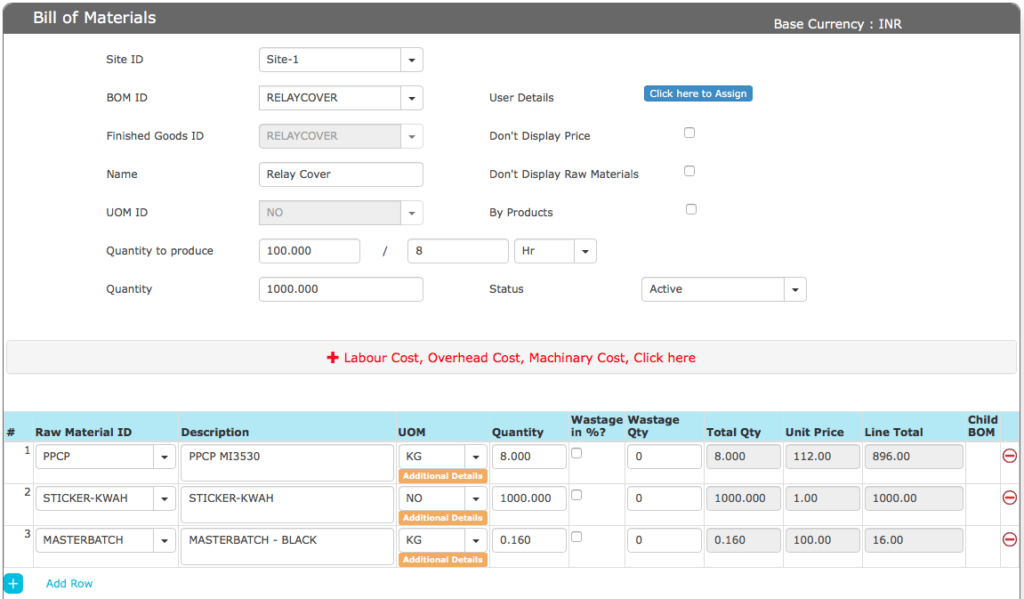

Multi layer Bill of Materials (BOM) / Product Structures.

Many production managers ask questions like

- What is BOM configuration?

- How to create a Bill of Materials (BOM)?

- How to Build a BOM

We are trying to address all these questions here with an explanation and what BOM really contains?

Multi Layer Bill of Materials (BOM)

Bill of Materials (BOM) is modified at the time of transactions and ensure that no one changes it. For the same item, you can have multiple BOMs and manage the productions. So you can define,

- Labor, Burden and other costs

- By-products, its costing etc

- Get the products estimated costs.

- Control the items that goes into Finished Goods

Advantage of ACTouch, Production Planning Software’s BOM feature is, you can find the exact product cost with cost deduction from By-products too.

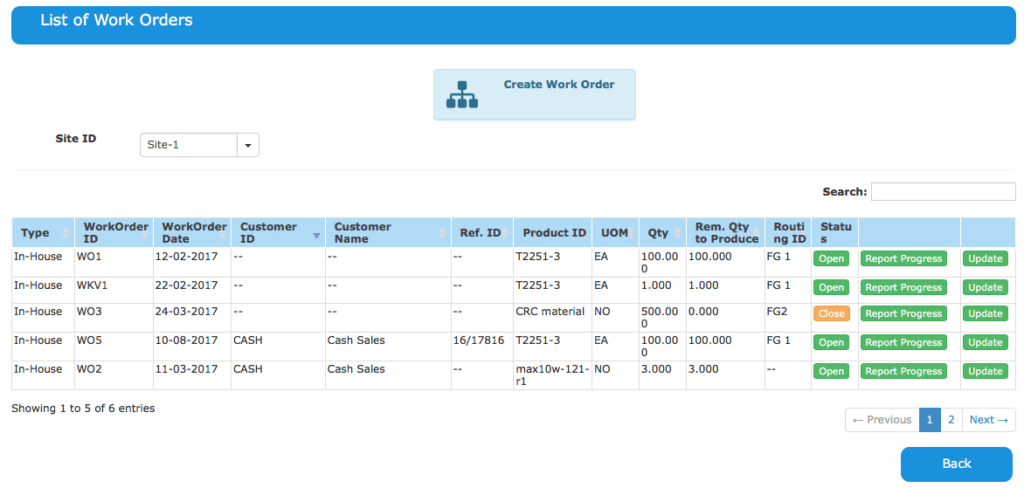

Work Order Dashboard

Many Business owners frequently ask these questions to their Production Manager.

- What is the status of my Production Delivery? Where we are and when we can meet customer demand?

- What is Work Order and how to speed up delivery?

- How long does this work order takes to complete the work?

Work Order and its process

ACTouch.com handles Work Orders with ONE Page activity. You can do

- Request for Materials transfer to Production Unit. (Material Request form)

- Semi or Finished Goods reporting.

- Send the Raw / Semi Finished materials for Subcontracting

- Receive the Finished Components from Subcontractor

From ONE page, you can manage the complete Work Order Operations. Now your Boss can see the details at one place.

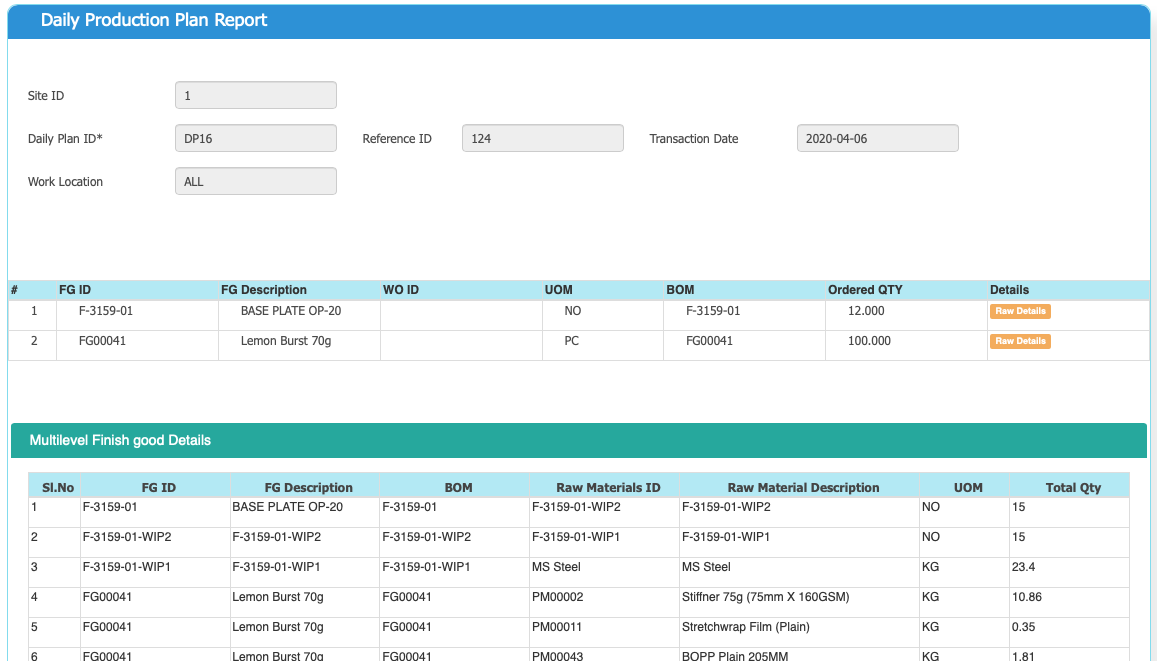

Daily / Weekly Production Plan

One of the main problem for Manufacturing companies, we are addressing is, you can plan for the multiple Semi or Finished Goods at a time and collect all the RM for them at one go from Stores. A powerful tool for the production manager.

Daily / Weekly Production Plan

ACTouch.com handles Daily / Weekly Production plan that helps

- Prepare the Production Plan for a week or month for 10 to 100 Finished Goods.

- Helps to process and generate ONE STOCK list to be collected from Stores

- If any Materials Shortages, please raise the Purchase Indents.

Powerful tool for Production Managers.

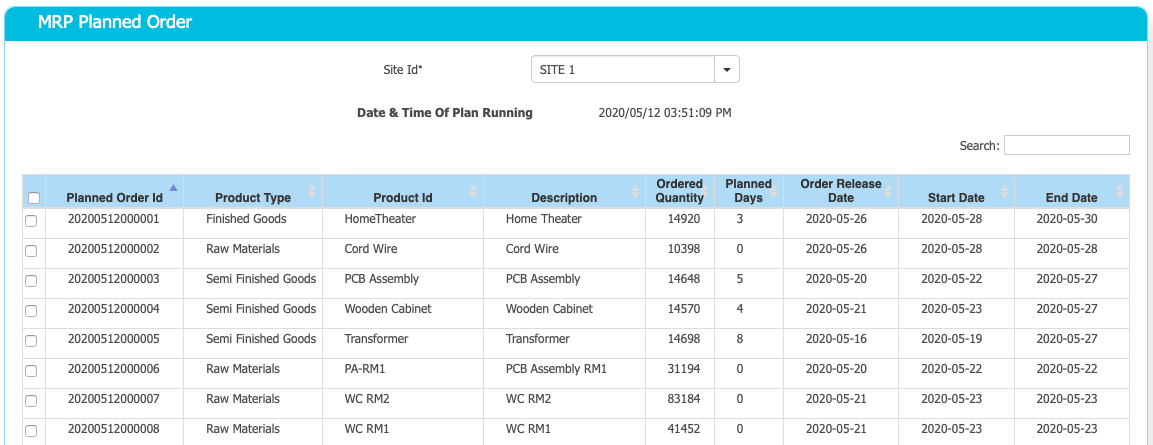

How Material Requirements Planning will work for me in Cloud Manufacturing ERP Software?

Material Requirements Planning or MRP is a powerful tool that helps you to manage your business with Demand and Supply. It’s a known issue that running a MRP in a Cloud Manufacturing ERP Software / on Premise environment is a challenge due to data load & bandwidth capability. Recommended to run after 10 PM.

MRP is a powerful tool.

MRP helps to check the demand (Sales, Forecasting etc) and checks the available stocks. Based on this it plans for the shortage of materials based on the timelines. The output of this is, it helps to generate planned orders for Production and Purchase Indents.

- Selective MRP

- Regenerative MRP

Choice is yours.