Contract Manufacturing ERP Helps to Manage Contract Manufacturers

What is Contract Manufacturing Company or a Contract Manufacturer?

A Contract manufacturer is the one, who takes Orders from OEM (Original Equipment Manufacturers) as per their design, Specification and does produce the Items and delivers as per the time schedule. Contract Manufacturer is paid for his efforts and materials, if any. Contract Manufacturing ERP helps the manufacturer to handle the demand and its Production, Deliveries, dispatch on time.

A good Contract manufacturing Company / Manufacturer can able to manage multiple Customer orders efficiently, economically and on time delivery. Depending on the need of Business, a Contract manufacturer can able to work on Discrete, Batch Process or Project Based product development and delivery.

So to achieve this,

He can either use additional Manpower with an Excel documents or a good ERP tool that’s designed for the Contract Manufacturing process.

Contract Manufacturing companies are special manufacturing units as they need to build their capability with a short notice from their customers.

There are few types of Manufacturing Units that are focused on the Contract Manufacturing.

- Discrete Manufacturing – Automobile, Injection Molding, Small Machines, Components manufacturing, Industrial products etc.

- Process Manufacturing – Chemicals and Medicines manufacturing, Foods and Packaging Industries.

- Best ERP for all the SMBs and it fits many verticals including for Contract Manufacturing companies and remote management.

These companies produce the Finished Goods based on the customer specification or design. Raw materials or Semi Finished goods are supplied by Customers and the Contract Manufacturing companies would process / Assemble and deliver to Customer.

It is also important to have a Customer centric ERP that could help to improve our contract manufacturing operations and delivery.

Looking for a Best Contract Manufacturing ERP Software? Click here

Contract Manufacturer and Contract Manufacturing Companies.

A contract manufacturer is a Contract Manufacturing Company or entity that is hired by another company to produce goods on its behalf. In this arrangement, the hiring company (often referred to as the “brand owner” or “client”) outsources the manufacturing process to the Contract Manufacturer, allowing them to focus on other aspects of their business, such as product development, marketing, and distribution.

Contract manufacturing is a popular business model across various industries, including electronics, pharmaceuticals, consumer goods, automotive, and more. It offers several advantages to the brand owner:

- Cost efficiency: Contract manufacturers often have specialized production facilities and expertise, allowing them to produce goods at a lower cost compared to the brand owner setting up their own manufacturing unit.

- Focus on core competencies: By outsourcing manufacturing, the brand owner can concentrate on research, development, marketing, and sales strategies, which are critical for their business growth.

- Scalability: Contract manufacturers / Contract manufacturing company can quickly scale production up or down based on demand fluctuations, providing flexibility to the brand owner without significant investments in infrastructure.

- Access to specialized skills and technology: Contract manufacturers often have experience and expertise in specific manufacturing processes or industries, giving the brand owner access to advanced technology and skills they might not have in-house.

- Reduced risk: As the contract manufacturer bears the responsibility of production, the brand owner faces lower operational risks, inventory management challenges, and manufacturing uncertainties.

The Contract manufacturing company relationship is typically governed by a legally binding agreement or contract that outlines the terms and conditions, responsibilities, quality standards, pricing, and intellectual property rights. The contract manufacturer is usually responsible for sourcing raw materials, managing production, ensuring quality control, and delivering finished products to the brand owner.

It’s important for both parties to establish clear communication and a solid working relationship to ensure the successful execution of the contract manufacturing arrangement. The brand owner needs to provide detailed product specifications and requirements, while the contract manufacturer must demonstrate their capabilities in meeting those specifications.

Overall, contract manufacturing is a strategic business decision that allows companies to leverage the strengths of specialized manufacturing partners to optimize their supply chain and focus on their core competencies.

We identified 3 major types of activities that happens here and based on that production is completed.

- Customer delivers all RMs and Semi Finished goods to his Contract manufacturer and after the assembly or final process, the Finished Good is sent back to Customer.

- Customer delivers Key Semi Finished goods and vendors add few of his items and assemble the Finished Goods.

- Vendor buys all the Materials and converts them into Finished Goods and sell back to the Customer.

In all the above three models, vendor is paid for his efforts and additional material costs that are incurred by him. However due to Accounting techniques, the process to recognise these Financial entires to book of Accounts is different.

In Summary, they need a right business tool to manage the below major aspects to make their customer happy.

- Reduce the cost of the production or at-least help them with accurate production cost details.

- Manage the quality process and improve the quality records.

- Ability to Plan and meet the customer delivery schedule.

Contract Manufacturing ERP has to solve the below challenges.

- How to separate Customer Inventory against our inventory – Detailed Inventory management tool to manage these challenges. Having multiple locations and Stores could help.

- How to track What materials and from whom it came? Track each customer materials separately.

- Manage Batch and Serial products across the companies.

- As the customer increases, the process and compliances becomes challenge. How to handle them?

- Multi Process Manufacturing companies – Manage the product demands with Reliability – Manage multiple types of manufacturing process for different customers.

- Discrete Manufacturing

- Process Manufacturing

- Large Machines manufacturing where the time period to complete the project is large.

A Contract manufacturing ERP like ACTouch helps the customers with following features.

Below are the few features that are important for a Contract Manufacturing ERP to support its customers.

- Multi level Bill of Materials – You can go to any level of materials.

- Batch Process Manufacturing.

- Traceability of Batch and Serial number items and its tracking

- Inventory management – In-house

- Customer inventory management

- Shop-floor controls, Work Orders and Production Management.

- Materials Requirements Planning (MRP)

- Bar-coding to simplify the process and ensure that selected data is accurate.

- API interface to report the Production Automatically.

- Site and Location level stock tracking.

- Product costing to know the ROI on the investments.

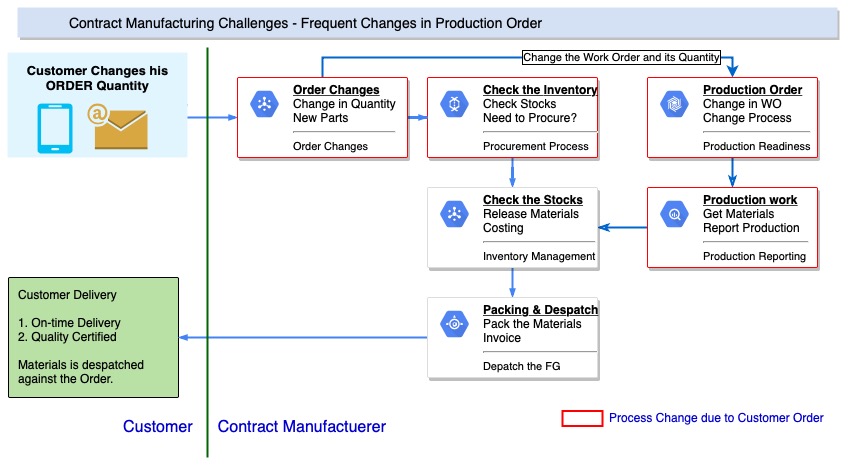

How to handle frequent Order changes from OEM? Any ERP for Contract Manufacturing should manage these process.

One of the major problems faced by Contract manufacturer is the frequent changes in the Order and due to this, their internal process changes. A contract Manufacturing ERP could help to resolve these changes and bring the control back to Business owners.