Subcontract Manufacturing or Contract Manufacturing

One of the major challenges for large companies in manufacturing industry to be ahead of their competition is by giving the large orders to Subcontractors and build their network. This process is called Subcontract manufacturing or Contract Manufacturing. This helps the large corporation to deliver the items in shortest possible of time with an army of Contract Manufacturers who ensures the right Quantity on time. This reduces the cost of manufacturing and delivery timelines too. Due to this reason “Job work for Subcontractors” activities or “Subcontract Manufacturing” or “Subcontracting” has taken importance and its an integral part of ACTouch ERP Systems.

ACTouch Enterprise Resource Planning Software will automate all the Subcontracting operations with Inventory Tracking at Subcontractor Locations, and also the remaining stock. When you make an Inward of Semi FG / Finished products from him, ERP would pass GL entries and updates stock too.

Benefits of subcontract manufacturing

Many Large manufacturing companies give their production order to their Subcontractors, who are External vendor, because

- They don’t have the necessary capacity to produce. They follow lean manufacturing processes.

- Timeline to do a manufacturing activities is very low. So subcontracting option is an important activities to manage the onetime production.

- They don’t have the necessary skill sets in in-house to do those manufacturing operations and convert to finished product. Example – Heat Treatment or Plating Operations.

- Internal cost of the development is more than subcontracting costs where the work is done at subcontracting location

- Helps to expand the business in shortest possible time

- Cost of manufacturing and risk of production is transferred to Contract manufacturers

- Intellectual property and specialized skills of new process belongs to Subcontractor and no one else.

What is Subcontracting Process / Approach?

Typically the large Manufacturer discusses with his vendors and agree for a Bulk Quantity to produce and its costs per pieces.

- The Raw materials are sent in small portions and not at one bulk go. Because of the prior contract, the rate per piece is agreed and followed by Subcontractors.

- Manufacturer will have his own Quality team that visits the Subcontractor / Subcontracting Location for Checks and Audits

- Subcontractor should follow the necessary process, testing certificates.

- Once the Finished products are done, vendor will send them to Manufacturer with Delivery Challans

- Stores will receive the materials and inspect and accept it.

- Customer will pay the money to Vendor on acceptance of the materials and rejection would be handled appropriately.

In ACTouch, below process will get key benefits to Subcontract Manufacturers

This is the process in which the Customer will send the RM to a subcontractor / vendor to convert the Raw Materials into a Finished goods. Customer will follow the below process

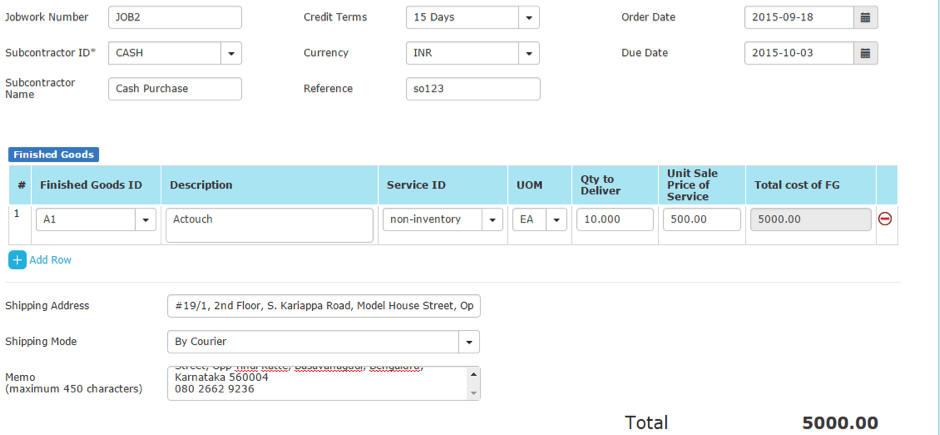

- Create a Job work order – This is an agreement between Customer and a Subcontractor with clear details like unit price per work etc for a manufacturing process.

- Outward Delivery Challan – Customer will make an outward DC and send the Raw materials to Subcontractor for his production process

- Here Customer will mention the FG and its Quantity to receive.

- Raw materials sent

- Inward Delivery Challan – Customer will make this document when he receive the FG and scrap items, if any. This reduces the stock that’s sent to Subcontractor

- Convert the Inward DC to a Purchase order and do the payments

Note: The Job wok, Inward and Outward DC layouts, field details etc are similar to JOB WORK For Customer menus.

Job work Order – The screen is as below with Subcontractor details and FG that would be delivered.

Check the videos of Subcontracting Manufacturing

More information, click here

- Check here the ACTouch’s ERP Features

- How to implement an ERP Software that’s easy and quick to do?

- Problems that are faced by an ERP implementation

For a FREE ERP Software Demo send an email to sales@actouch.com

|