We are trying to address many questions and related to Work Order Process and its advantages and disadvantages etc.

Finished Goods Reporting is a process to receive the Finished Goods into ERP and at the same time consume Raw Materials. Based on the Business needs customer will follow different process.

- Directly do a FGR and receive the Finished Goods – Firms who have less items and are controlled by close monitoring can follow this model.

- Manually do the Materials Request Form (MRF) and based on the receipt of materials to the destination locations, production reporting is done.

- Work Order Process – If you want to manage the internal process, it has complex multi process etc, please follow this. Advantages of this is

- Helps to define a set of operations / steps to complete to arrive at the Finished Goods (Routing process)

- Define the Work centres, where the real work happens as the Stores Person can transfer the RM to the location.

- Pre-Define the Process, where the Subcontracting Operation happens. This avoids the last minute confusions.

In this module, we try to address the following.

- What is Work Order process?

- How to setup a process?

- What are the steps to follow and master data needed?

- Advantages of setting up of a Work Order Process?

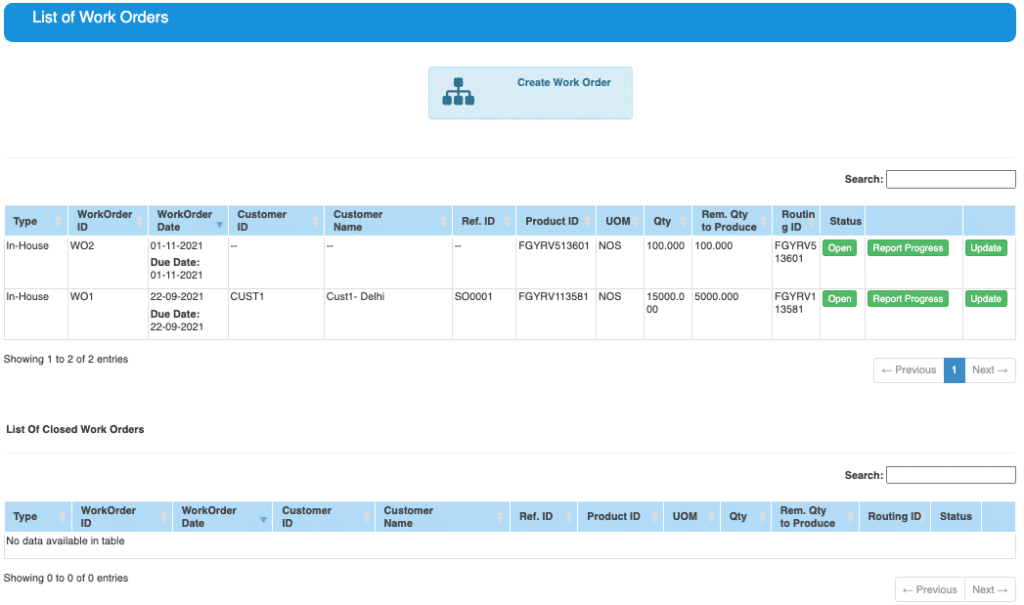

Work Order Dashboard with Open and Closed Work Orders.

Master Data needed to manage an efficient Work Order Process

- Product Master

- SO and its settings, incase, you convert a Sales Order to a Work Order.

- Manufacturing settings

- Bill of Materials

- Operations.

- Tools, if any

- Work centre

- Routings.

- Customer / Supplier Master for subcontracting.

- Batch Numbers, if any.