What is Customer IDC (Inward Delivery Challan)?

Customer IDC / Inward Delivery Challan is created when we receive the Raw Materials from customers and we need to track them separately against the customer IDC. In ACTouch ERP, we have built a strong mechanism to hold and track these materials received from each Customer and these are NOT added into your Inventory. For example

- MS Steel of 100KG is sent by Customer 1.

- MS Steel of 78KG is sent by Customer 3.

At the same time, you have your own inventory of MS Steel of 22KG with you. So technically on your STORES / SHOP FLOOR, you have 200KG, MS Steel.

But 178 KG doesn’t belong to you.

Video that helps on how to make an IDC and ODC documents for the same.

How you handle it Customer Inward Delivery Challan?

ACTouch ERP handles these cases with keeping the stock separate for each customers and tracking them one to one. So it is easy to track who sent what items and how many are remaining now?

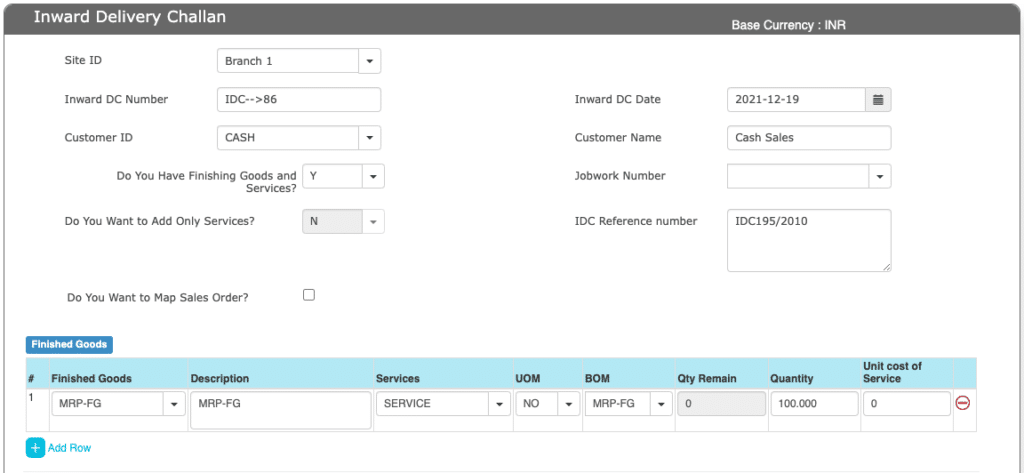

Customer IDC main screen.

Few fields are important to follow as they OPEN few MENU options to work.

- Do you want Finishing Goods and Services = Yes / No – This option helps you to enter both “FG with services” and helps to pre-define the RMs for the same.

- Do you want to Add Only Services = Yes / No – If you want to mention only the “Services” and don’t know which FG to create?

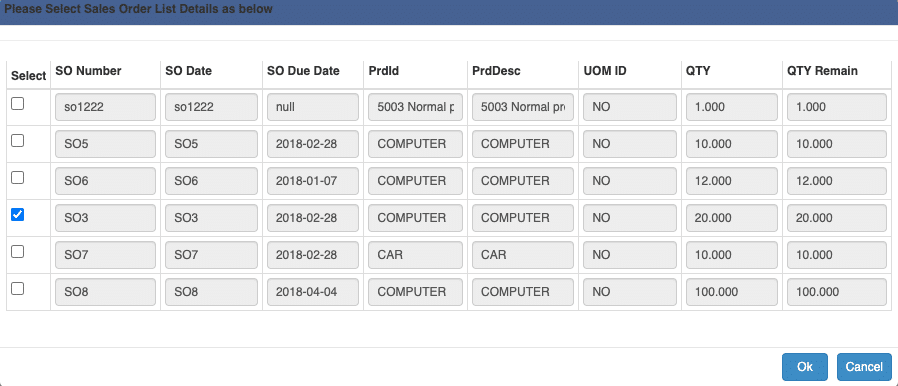

- Do you want to Map Sales Order = Yes / No – Helps to MAP the SO Line item to this Inward DC. Helps when you are sending the SO and map to IDC materials.

Mapping of SO Line items with quantity to IDC line items.

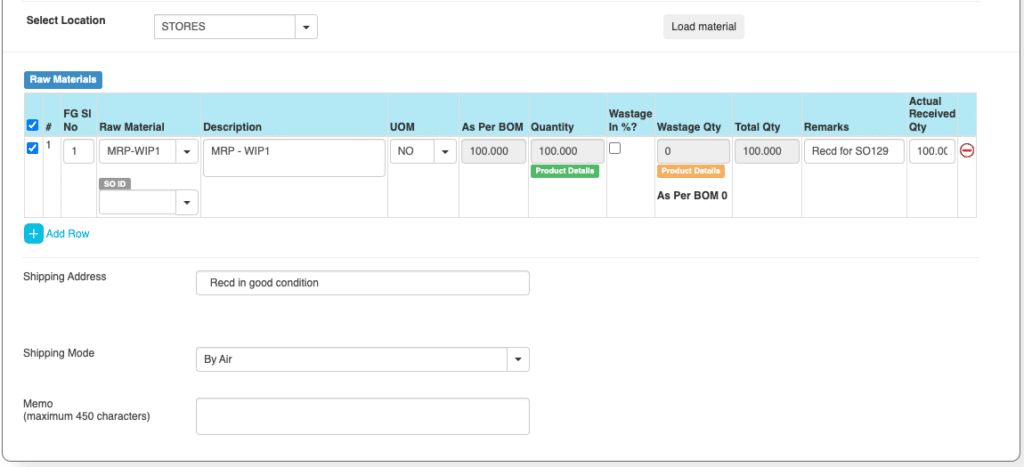

Enter the Line items to receive the RM to our Location. Internally ERP will block the materials at these location to track against the Customer IDC data.

Below are the details to enter.

| No | Field ID | Field name | Mandatory | Field description and how it helps? |

|---|---|---|---|---|

| 1. | Inward DC Number | IDC No. | Yes | IDC Number can be generated automatically or its entered manually. Most of the companies will have a ONE SERIES for the customer Jobwork tracking as well as for the Subcontractors FG that comes in. |

| 2. | Customer ID | Customer ID | Yes | It’s a unique ID for a customer |

| 3. | Do You Have Finishing Goods and Services? | Yes / NO | No | Many times, when the RM comes from customers, the vendor may not know “the work” to do. These instructions come at later dates. If you know the FG / Services to be done then set it as “YES” and enter the FG and Services ID. |

| 4. | Do You Want to Map Sales Order? | This helps to connect to the SALES ORDER against which this service is given. Helps in despatching the items as the work completes and track them. | ||

| 5. | Inward DC Date | Inward DC Date | Yes | DC date. |

| 6. | Customer ID and Name | Customer ID and Name | Yes | Customer ID and Name from whom, we received the materials. |

| 7. | Job work Number | Unique job work number | Yes | It’s the unique identification number given to each job work taken from the customer. If you have a Jobwork with the customer then you can use it to receive the Materials against the same. |

| 8. | IDC Reference Number | Reference information | Yes | It’s the additional information provided for internal reference and inventory management. |

| 9. | Finished Goods (FG) | Finished Goods ID | Yes | What is the FG to be developed and sent to Customer? |

| 10. | Description (FG) | Finished Good Description | Yes | FG Description. |

| 11. | Service (FG) | Service provided | Yes | It gives us what kind of service is being provided. Based on this, we can charge the customer. |

| 12. | UOM (FG) | Unit of measurement | Yes | FG’s UOM. |

| 13. | BOM | BOM ID | Yes | Which BOM ID to be used to consume the RMs. |

| 14. | Qty Remain (FG) | Remain quantity to be delivered | Yes | It gives the remaining quantity of finished goods to be delivered to the customer. |

| 15. | Quantity (FG) | Quantity measure | Yes | Its gives the total number of Finished Goods produced. |

| 16. | Unit Cost of Service (FG) | Cost of service/ Unit | Yes | Its gives the cost of service for producing one unit of the Finished Good. |

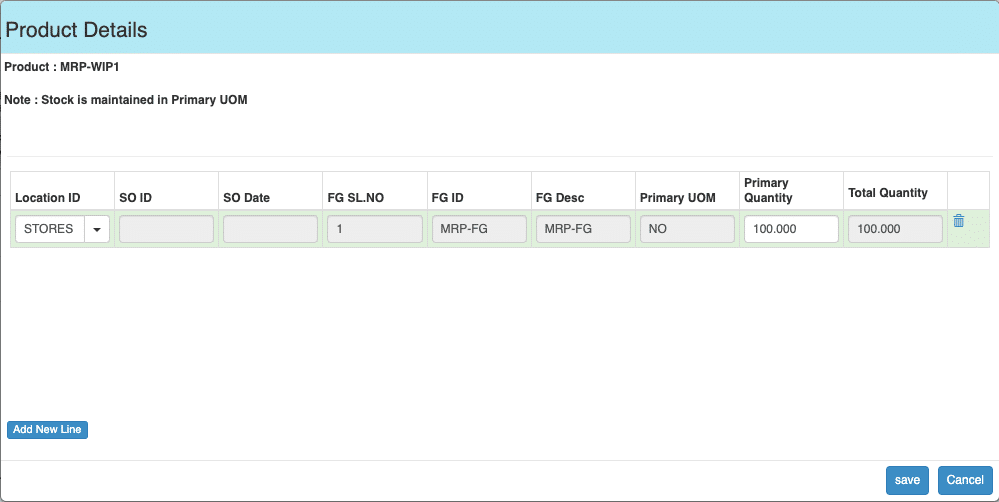

| 17. | Select Location | Location of RMs that to be consumed | Yes | This helps ERP to choose the location from where the RM to be auto picked and consumed. |

| 18. | FG Sl No (RM) | Finished Good serial number | Yes | It gives serial number for the Finished Goods that is associated with that particular Raw Material for easy Identification of the Raw Material. |

| 19. | Raw material (RM) | RM ID | Yes | RM ID that’s received by you. |

| 20. | Description (RM) | Raw material description | Yes | It describes what kind of raw material we are using to develop the finished good. |

| 21. | UOM | Unit of measure | Yes | It is the magnitude of the quantity.It can be kg, litre, etc. |

| 22. | Quantity | Quantity measure | Yes | It gives the amount of any specified raw material. |

| 23. | Wastage in % | Percentage Wastage of the RM | Yes | It gives the probable wastage in %age. (Expected) |

| 24. | Wastage Quantity | Quantity of wastage | Yes | Total amount of wastage accrued while producing the finished goods. This is as mentioned in the Bill of Materials. |

| 25. | Total Quantity | Total quantity of the raw material used. | Yes | It gives the total quantity of the raw material used to develop a finished good. |

| 26. | Remarks | Remarks | Yes | It provides particular remarks regarding the raw material if any. |

| 27. | Actual Received Quantity | Actual quantity of RM received | Yes | It gives us the total quantity of the raw material received from the customer end. |

| 28. | Shipping Address | Address to be delivered to | Yes | It gives the destination address to where the Raw Material has to be delivered to. |

| 29. | Vehicle courier details | Vehicle /courier details | Yes | This describes the vehicle and courier details such as transporter name, courier name, vehicle number, etc. |

| 30. | Gate pass Id | Gate pass identification detail | Yes | This gives the customers gate pass id detail. |

| 31. | Gate pass Date | Gate Pass Date | Yes | This gives the date on which the seller dispatches the Raw Material. |

| 32. | Transporter Name | Transport Organization Name | Yes | This is the name of the organization which is responsible for transporting the Raw Material. |

| 33. | Transporter GSTN | Transporter Tax ID | Yes | This gives Transporter TAX NO. It’s a unique ID necessary for businesses. |

| 34. | Vehicle No. | Transporter Vehicle Number | Yes | This gives the Transporter Vehicle Number which transports the Raw Material to the contractor or business. |

| 35. | Courier Name | Courier Agency Name | Yes | This is the Courier Agency Name responsible for delivering the Raw Material to the contractor or businesses. |

| 36. | Courier Branch | Courier Agencies Branch Name | Yes | This gives the Courier Agencies Branch which is responsible for delivering the Raw Material. |

| 37. | Courier Date | Date of product dispatch | Yes | This gives the date on which the Raw Material was dispatched. |

| 38. | Docket Number | Vehicle registration number | Yes | This gives the vehicle registration number of the transporting vehicle. |

| 39. | GC / LR Date / Ship Bill Date | Receipt of the lorry | Yes | It is the receipt of the date that specifies the landing date and it’s the receipt that we receive from the transporter. |

| 40. | GC / LR Number / Ship Bill Number | Lorry receipt number | Yes | This gives the lorry receipt from the transporting company. |

| 41. | Packing Date | Date of package | Yes | This tells us the date Raw Material was packaged. |

| 42. | Packing Number | Product package number | Yes | This gives the number allotted for the package. |

| 43. | Number of Packages | Total number of package | Yes | This gives the total number of packages to be delivered. |

| 44. | Weight of Packages | Total weight of the packages | Yes | This gives the total weight of the packages to be delivered. |

| 45. | Shipping Mode | Mode of Delivery | Yes | It gives the transportation mode by which the Raw Material will be delivered to the destination.Ex: By Air, Cargo etc. |

| 46. | Memo | Memo | Yes | It gives the description of the Raw Material and details related to the particular Finished Good. |