What is Customer Outward DC (Delivery Challans)?

In Job Work business, you receive the RM’s from your Customer with instructions on what to do with it and when to deliver the FG etc. As we complete the work, we have to report back to customer on the completion of FG and also report the consumption of RM that he has sent. Customer outward DC (delivery Challan) helps to send the FG back to customer, reporting the consumption of RMs.

Customer Outward DC helps us to handle this needs. We create the ODC with what FG and numbers we are sending with the RM that’s consumed against this production.

Here we match against the RM that’s received through inward process. This helps us to connect to end to end connection between what we received, how much we consumed and how many FG we sent to customers.

Video – How to receive the materials from Customer and send FG to customer. (Outward DC)

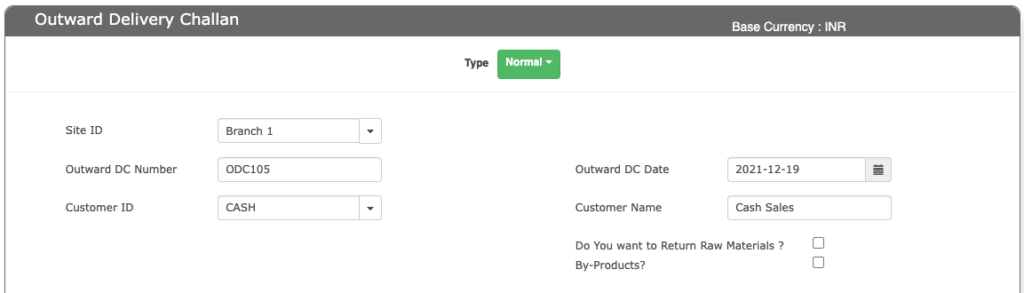

Outward Delivery Challan menu

Here there are few fields that are important for the transaction to happen.

- Do You want to RETURN the RM = YES / NO – This helps to return the RMs and not report any FG and consume any RM. This happens in business, where the customer decides to change the production plans or ask to return the RMs.

- By-Products = YES / NO – This helps to report and send the BY-PRODUCTS thats produced as part of RM conversion to FG.

Both above fields are important in the process of creating Outward DC.

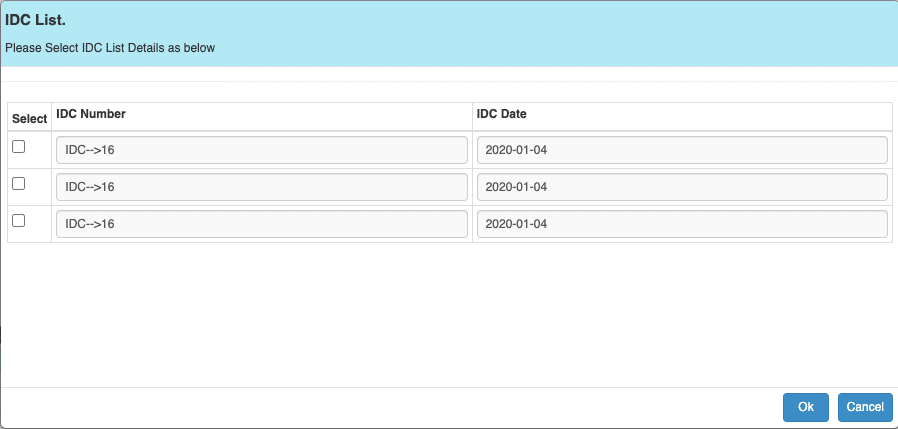

Once you select the Customer ID, the application will show the list of the Inward DC thats done to receive the RMs from the same customer.

You can either select ONE IDC or Multiple IDC to report the FGs.

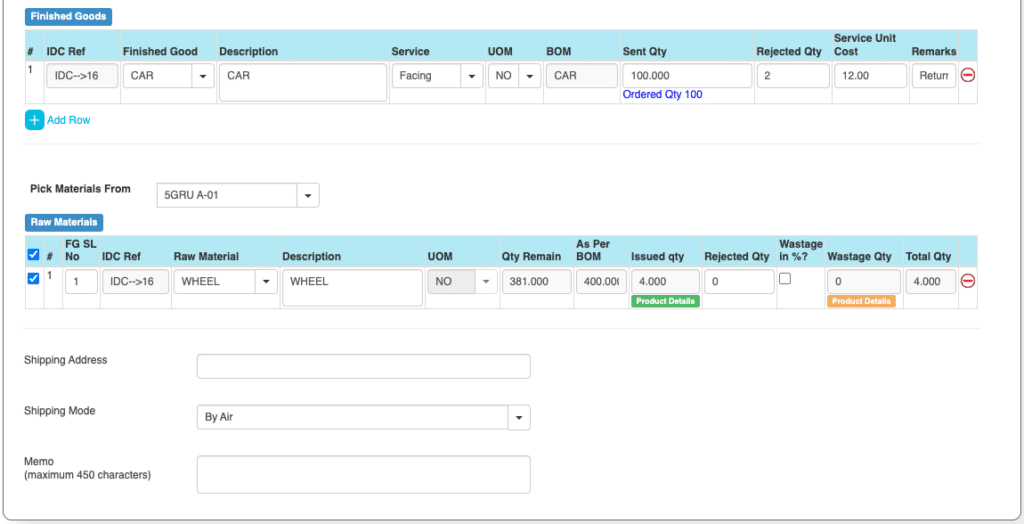

Against the IDC, we report the FG and the RM consumed towards the same. The application will show the cost of materials consumption and FG services costs too.

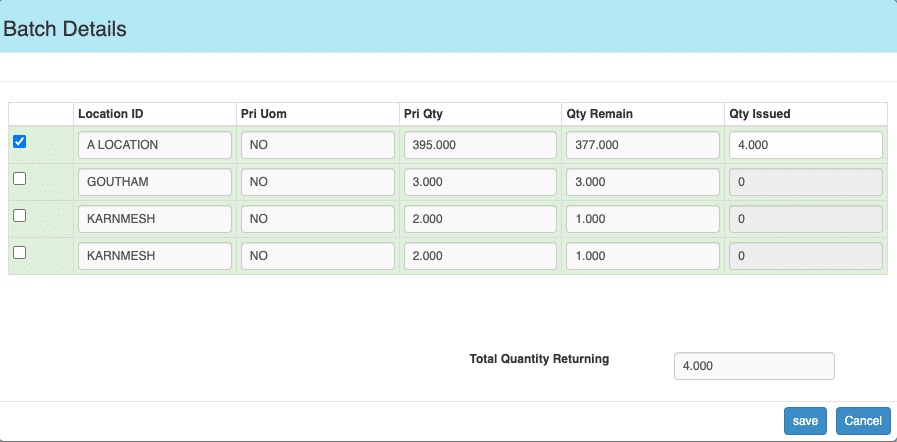

Below details show the IDC and its location where the RM is kept in the system.

Field details for the Outward DC screens are as below

| No | Field ID | Field name | Mandatory | Field description and how it helps? |

|---|---|---|---|---|

| 1. | Outward DC Number | Outward DC No | Yes | Outward DC No can be added manually or allow the Application to generate them automatically. |

| 2 | Outward DC Date | Outward DC Date | Yes | The date on which the Finished Goods was sent to the customer. |

| 3. | Customer ID | Customer ID | Yes | Customer ID |

| 4. | Customer Name | Customer Name | Yes | It gives the name of the customer to whom the Finished Good was sent to. |

| 5. | Do You want to Return Raw Materials? | Return of Raw Material | No | When you receive the RMs, you have the option to consume and convert it to a FG or Return the material, in case you have extra ones. It gives us an option to select and send back the Raw Material if there is any return of Raw Material due to damage or due to excess of Raw Material left out after processing of the Finished Good. |

| 6. | By-Products? | By-Products | No | When you report the FG, you have the option to report the materials that are produced as By-products. These can have value and need to track for inventory too. |

| 7. | FG Sl No (RM) | Finished Good serial number | Yes | FG SL No. |

| 8. | IDC Reference Number | Reference information | Yes | When you make an ODC, we link the same to the Inward of RM. This helps to ensure that whatever the materials that we received are consumed / converted to FG and sent back to Customer. |

| 9. | Raw material (RM) | Raw material identification number | Yes | RM ID and the items that’s consumed here. |

| 10. | Description (RM) | Raw material description | Yes | It describes why the Raw Material is being returned. Reasons may be due to damage or excess of stock of raw materials. |

| 11. | UOM | Unit of measurement | Yes | It is the magnitude of the quantity.It can be kg, litre, etc. |

| 12. | Quantity | RM Quantity | Yes | It gives the amount of any specified Raw Material. |

| 13. | Wastage in % | Percentage Wastage of the raw material | No | It gives the total percentage of the wastage of the raw material while producing the finished good. |

| 14. | Wastage Quantity | Quantity of wastage | No | Total amount of wastage of the Raw Material accrued while producing the finished good. This is as mentioned in the Bill of Materials. |

| 15. | Total Quantity | Total quantity of the raw material used. | Yes | It gives the total quantity of the Raw Material which was unused or damaged. |

| 16. | Quantity Remain (RM) | Remain quantity to be delivered | Yes | It gives the remaining quantity of Raw Material to be delivered to the customer. |

| 17. | Rejected Quantity | Rejected quantity | Yes | It gives us the total quantity of the Raw Material rejected due to damage or defect. |

| 18. | Issued Quantity | Raw material quantity issued for return | Yes | It gives the total quantity of the Raw Material issued for return due to damage or defect. |

| 19. | FG Sl No (by-product/scrap) | Finished Good serial number | Yes | It gives serial number for the Finished Goods, which is associated with that particular by-product (scrap) for easy Identification of the by-product (scrap). |

| 20. | ODC Reference Number | Reference information | Yes | It’s the additional information provided for internal reference and inventory management. |

| 21. | By-Product ID | By-Product ID | No | It is the unique identification number given to the By-products obtained while reporting Finished goods. Usually it is scrap that is generated. |

| 22. | Description | By-product description | No | By-Product description. |

| 23. | Quantity in % | By-product quantity in percentage | No | It gives us the percentage of scrap produced while producing the finished goods. If this field is not selected then we will be directly taking the quantity of the scrap into consideration ignoring the percentage quantity of the scrap. |

| 24. | Total Quantity | Total Quantity of the by-product (Scrap) | Yes | It gives the total magnitude of quantity of the scrap we get after calculation of percentage of the quantity. |

| 25. | Quantity As Per BOM | Total quantity of the by-product/scrap as per Bill of Material | Yes | It gives us the total quantity of by-product/scrap as mentioned in the Bill of Material (BOM). |

| 26. | Shipping Address | Address to be delivered to | No | Address where the FG and others are sent to. |

| 27. | Shipping Mode | Mode of Delivery | No | How the material is sent? |

| 28. | Memo | Memo | No | Any comments or data to report. |