Daily Production Plan is an option that helps Factory Manager to plan for the complete STOCK required for a Production unit once for all. For example, few manufacturing companies produces similar items in their factory and RM required for them is of similar nature.

So how to plan for these common items together?

Material Requirements Planning helps to plan for the RM / Semi FG based on the total DEMAND. But the challenge here is EACH ITEMS HAVE A DIFFERENT DUE DATEs as ERP does a backward schedule. But customer wants a SINGLE CONSOLIDATED DEMAND for materials to be generated without any DUE dates. So that they can combined the NET DEMAND and place one PO.

Let me explain with an example.

- RM1 – 100KG. by 01- Jan 2023

- RM1 – 122KG. by 10- Jan 2023

- RM1 – 12KG. by 21- Jan 2023

If you look above examples, we need same RM at different DATES based on production. So the customer has to place 3 Purchase Orders with VENDOR. This leads

- Loosing an opportunity negotiate better price.

- Pay for extra materials handling charges.

- Increased workload for Stores, Purchase and Payment departments.

So Daily Production Plan module is designed to handle the above cases including Production Planning.

Now, you can plan for the materials based on FG and weekly schedule.

- One day materials needed

- Weekly Materials needed

- Monthly total materials needed.

Please refer to this document to Understand more about the Daily Production Plan and how it works

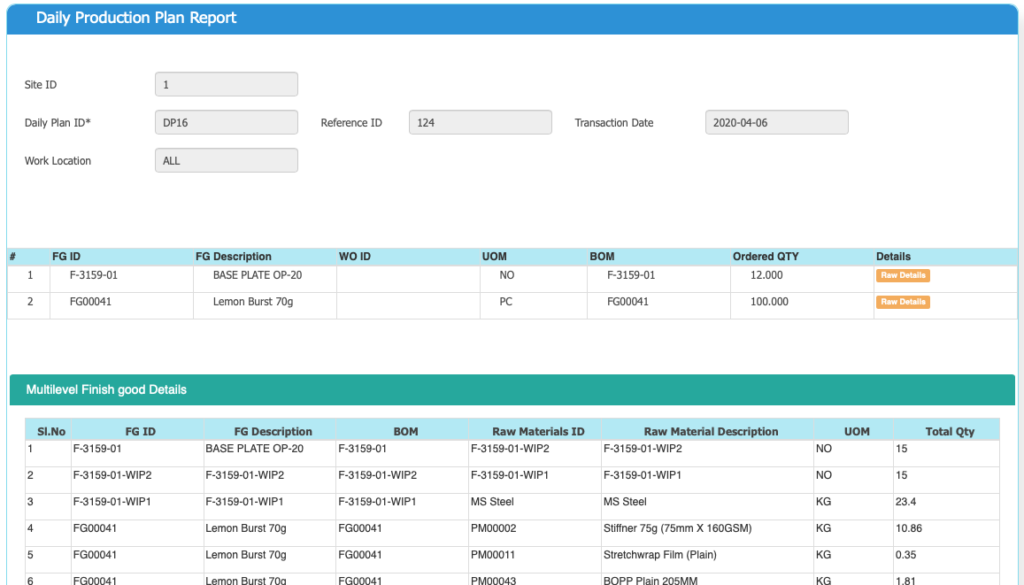

As the image shows the details of 2 Finished Goods and its consolidated RM / Semi FG needed to complete the tasks.