Manufacturing functions contains features like

- Few of the below Master data has to be prepared before the process begins.

- In-house Production

- Focusses more on the Production, Finished Goods Receipts (FGR), Tracking of Production etc

- Subcontracting Operation

- Helps to make an Outward Delivery Challans

- Inwards the FG based on the RM that’s sent to vendor.

- Job Work operation for Customers.

- Helps to inward the RM sent by Customers

- Convert them to FG and receive the service fees from customers.

There are many more surrounding features that helps customers to manage the business.

- Demand Notes for Project based work – Demand Notes features that helps to issues the materials for the work, block the materials and consume against the FG reporting

- Materials request form (MRF) – Helps to raise the materials request and transfer the materials against the MRF to the destination location

- Materials requirements planning (MRP) – Helps to plan the materials based on demand and supply of products.

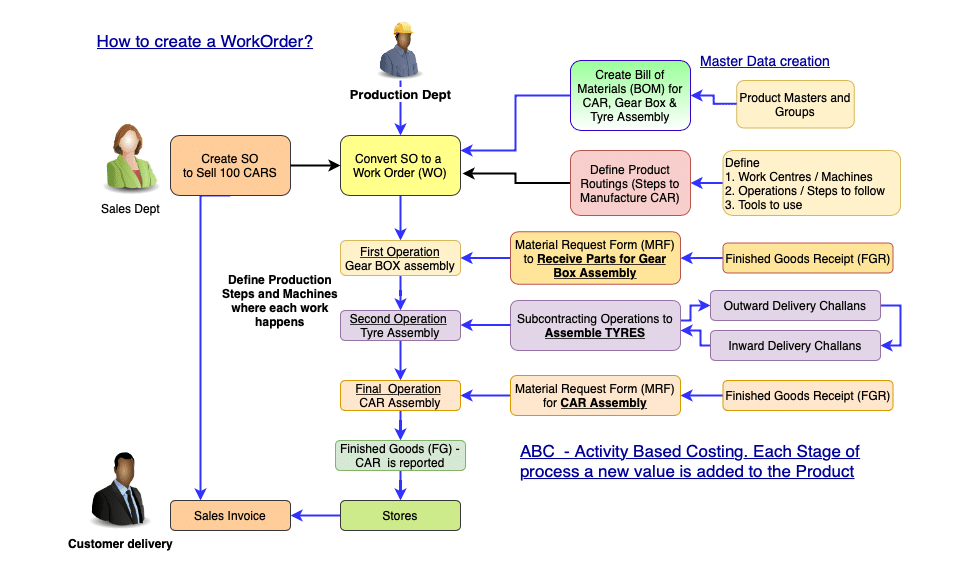

- Work Order Process and management.

Work Order helps to manage the business efficiently with defining of Work Centres (where the work happens), Routing (defining the multiple steps of production) and connect them to Work Orders.

Overall Manufacturing Functions are summarised as below

Above image shows the features and functionality thats built in ACTouch ERP.

We have customers from below manufacturing verticals. Check do we fit your vertical?

- Injection Molding

- Electronics Manufacturing

- Forging and extrusion.

- Automobile and Farm Equipments Components.

- Medical Devices

- Small and Large Machine Manufacturers

- Packaging Industries

Articles

- Manufacturing Settings

- What is Bill of Materials (BOM)?: 100% Great Guide with BOM examples

- What is Activity Based Costing?, 100% Guide on ABC Costing and Examples

- Finished Goods Reporting (FGR)

- FG Reporting with Batch Number Traceability

- Material Request form (MRF)

- MRP Process – What is MRP? 100% great way to configure ERP for better results.

- Daily Production Plan