How to Create Locations Master for Manufacturing units?

“Location” means the place where the Items / Products are STORED / KEPT. So we need to create Locations in ERP even before we begin to start entering the operations / transactions. However decision to use this feature depends on each Business and ACTouch ERP helps to configure the ERP as per your needs. It is important to do a location master data management based on user access rights, what activities to done here, who is responsible etc.

Is this Mandatory = Yes / No.

The decision to use this feature depends on your business needs. Traders, who focus on BUY and SELL, may not be needed to use it. However it is Important for MANUFACTURING Companies.

This feature helps to group the items and identify what to do with them. It’s like keeping OIL, Diesel in the DRUMS or keeping steel bars in the STORES etc. In few business cases, the RACKS where the items are kept is mentioned as “LOCATION” that helps the person to pick the items. It helps new person who joins company to FIND where THIS ITEM is STORED.

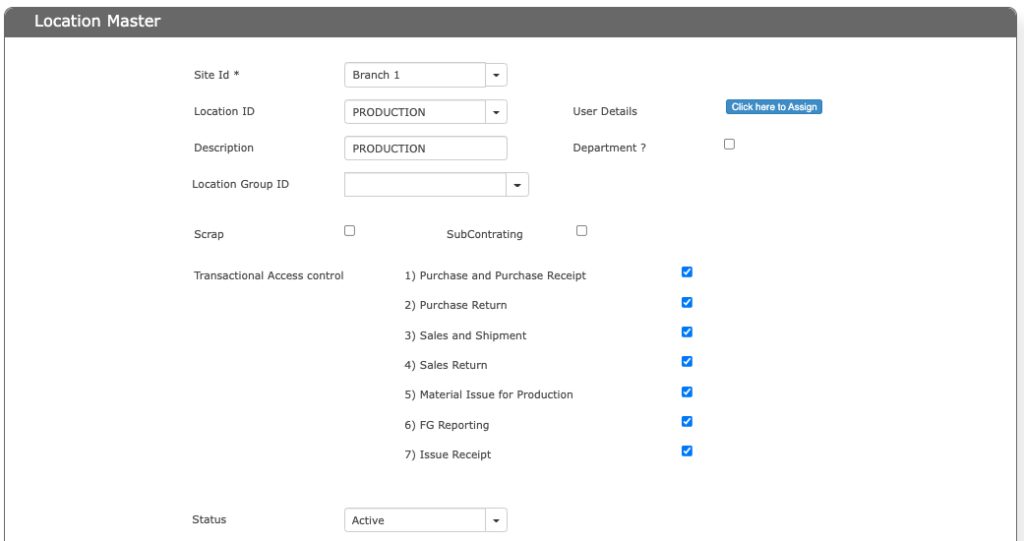

Create Location Master

“STORES” location that’s where all the MATERIALS are kept under control and issued to “PRODUCTION” location where the WORK happens. If these materials are rejected, then the Production team will move these items to “REJECT LOCATION”, so that its not USED by anyone else.

We built location master with 3 important features

- User access rights – You can identify the person / persons who has ACCESS to this LOCATION. For example, a PRODUCTION PERSON shouldn’t have an access to “STORES” location to use the items.

- Permission to do Transactions – For example, in “REJECT LOCATION”, we should not receive the items or do the SALES Activities.

- “Subcontracting = Yes / No” – This helps ACTouch ERP to identify those locations that are NAMED for SUBCONTRACTOR materials to track and helps to TRANSFER the materials to these VENDOR location in OUTWARD DELIVERY CHALLANs. This process helps to keep tracking of material sent to Vendor and how much is still remaining with them.