What is Subcontracting?

Subcontracting is a process of sending / outsource the RM to a designated vendor with an instruction to convert them to a desired outcome as per the business needs. Subcontractors are paid for this service once the delivery happens.

Subcontracting process is a process to de-risk the work loads or not to invest more into specific technology, thats not part of the main business focus. Types of subcontracting or a process of subcontracting or type of subcontracting services needed depends on project requirement and nothing else.

Subcontracting process is done for a specialized skills needed to meet the production demands. It’s a contractual agreement between an independent contractor or a company to delivery entire project or a partial of it. Its mainly done to avoid project risks like time delays or need of specialised skill sets, cost savings etc.

Business owners will decide to give a work to prime contractor who could able to deliver what he promises and also generates many benefits of subcontracting to owners. its a 100% business arrangement. Subcontracting arrangement is quite common in manufacturing industry, construction industry, construction project etc. Whether business owners need a specialized subcontractors or a normal workers depends on project details.

What is Subcontracting and How an Outward Delivery Challan helps Subcontractors?

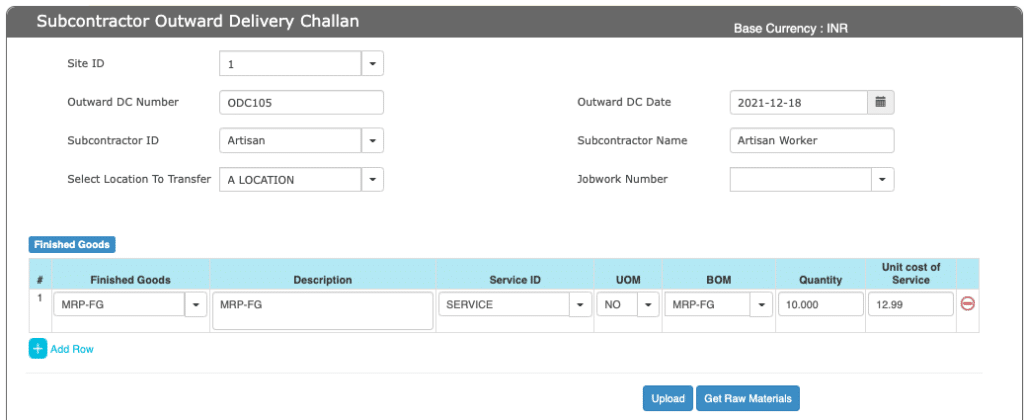

Outward delivery challan or ODC is the document that’s sent to the Subcontractor or a vendor as part of Subcontracting process to convert the RM sent to him to a FG. He is doing the Job Work for your product.

Typically when you are short of machine capacities or work load more and time to delivery is less, you would be subcontracting the work to another party who has the machine capability to execute the work. Few cases, the vendor has an additional capability to execute work.

We focus on following important points here

- Subcontractor to whom the materials been sent

- Location ID to which the materals is transferred in the ERP (Its an important aspect that these material belongs to you and you need to track and see how much is sent to Vendor)

- List of Finished goods that are expecting from the vendor and an agreed price per unit.

- Raw materials that are sent to the vendor.

ACTouch ERP handles the services cost to be added to Product Cost with RMs. This helps to get your FG costs as acuurately as possible.

What is Subcontracting- Important Note on Subcontracting process

- In ACTouch ERP, we use the LOCATION Feature to track the materials sent to Customer.

- So create the LOCATION IDs in the name of VENDORS.

- When you are sending the materials to Subcontractor through the Delivery Challans, internally ERP would transfer the materials to the VENDOR LOCATIONS.

- This helps to know “how much of your materials are lying at vendor place”.

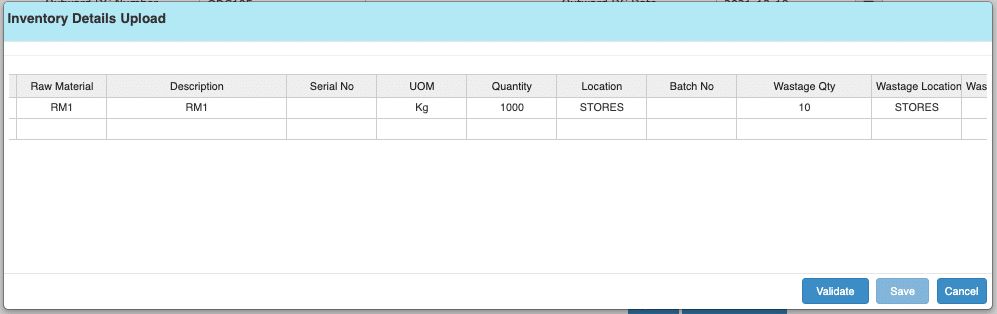

Note: ODC Line upload feature. You can use this feature, if

- You have a frequent changes in the Raw Materials and Quantity to send to customer.

- You need to change the Quantities as per your packages and not as per BOM.

Here you enter the Product ID, Quantity and pick the location from where the materials is transferred to Subcontractor Location.

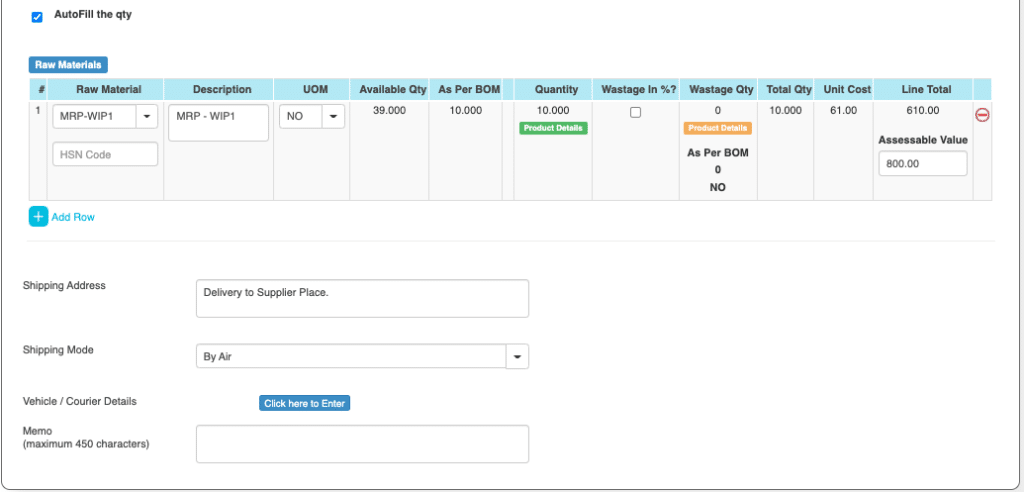

Subcontracting ODC Line Details.

Enter the Items that are sent to vendor and from which Locations.

“Assessable Value” helps to define the actual value of an item and this appears on the DC PRINT.

Field Details are as below.

| NO | Field ID | Field name | mandatory | Field description and how it helps? |

|---|---|---|---|---|

| 1. | Outward DC Number | Outward Delivery Challan Number | Yes | It gives the Outward Delivery Challan number for the materials that is sent to the subcontractor. |

| 2. | Subcontractor ID | Subcontractor / Vendor ID | Yes | A unique Subcontractor / Vendor ID to each and every Subcontractor who is assigned the job work to be done. |

| 3. | Subcontractor Name | Name of the Subcontractor | Yes | It gives the name of the subcontractor to whom the job work is assigned to. |

| 4. | Outward DC Date | Outward DC Date | Yes | The date on which the Raw Material sent to the Subcontractor. |

| 5. | Select Location To Transfer | Raw Material transfer location | Yes | This gives the location of the subcontractor to which the Raw Materials have transferred to. |

| 6. | Job Work Number | Job work number | No | In few cases, customer may have an agreed Unit price and Quantities with a Vendor and that’s called “Jobwork Order”. This states the items, work to be done and the total quantity to worked on. This is similar to a “blanket Order” that helps to negtiate better prices. When you use the Jobwork Order, ERP will check the Quantity remaining when you convert to an ODC and stops, if the Jobwork Order doesn’t have sufficient Quantities to send. |

| 7. | Finished Good ID | FG ID | Yes | FG ID that’s expected to be received from vendor. You can add multiple FGs and send RM for the same. |

| 8. | Description | Finished Good description | Yes | FG Description. |

| 9. | Service ID | What type of Service is provided | Yes | It defines the Services ID indicating what kind of services is expected. This is linked to Unit Price.For example – Blackening, Plating, Machining etc. |

| 10. | UOM | Unit of measurement | Yes | Unit of Measurement. |

| 11. | Quantity | Total Quantity expected | Yes | It tells us about the total quantity of the Finished Good to be delivered by the Subcontractor. |

| Bill of Materials ID | BOM ID | Yes | It is the unique identification number given to each bill of Material. Based on this BOM ID, application will List the RM required. | |

| 12. | Unit Cost of Service | Cost of service for one unit of Finished Goods | Yes | It gives the Unit price for the Service of a Single Finished Goods. |

| 13. | Raw material | RM ID | Yes | RM ID that’s been sent to Subcontractor |

| 14. | Description | Raw material description | Yes | RM product description. |

| 15. | UOM | Unit of measurement | Yes | Units of measurement of the Product |

| 16. | Quantity | Quantity | Yes | RM sent to vendor |

| Location ID | Location ID | Yes | Location ID helps to identify the location from where the RM is sent. | |

| 17. | Wastage in % | Percentage Wastage of the raw material | Yes | It gives the total percentage of the wastage of the raw material while producing the finished good. |

| Location ID | Location ID | Yes | “Location ID for Wastage Quantity” helps to identify the location from where the RM is sent. | |

| 18. | Wastage Qty | Quantity of wastage | Yes | Total wastage quantity accrued while producing the Finished goods. This is as mentioned in the Bill of Materials. |

| 19. | Total Qty | Total RM Quantity Sent | Yes | It gives the total quantity of the RM that’s sent to vendor. |

| 20. | Unit Price | Price of a single unit of raw material | Yes | It gives the price of one single unit of the raw material used for making a finished good. |

| 21. | Line Total | Total price of the raw material used | Yes | It gives the total amount of the particular raw material used.Total Qty*Unit Price = Line Total |

| 22. | Shipping Address | Address to be delivered to | Yes | Address to where the RM is sent. |

| 23. | Shipping Mode | Mode of Delivery | Yes | It gives the transportation mode by which the Raw Material will be delivered to the destination.Ex: By Air, Cargo etc. |

| 24. | Memo | Memo | Yes | Additional information to the Subcontractor, if any. |

| 25. | Vehicle courier details | Vehicle /courier details | Yes | This describes the vehicle and courier details such as transporter name, courier name, vehicle number, etc. |

| 26. | Gate pass Id | Gate pass ID | Yes | This gives the Company gate pass id detail. |

| 27. | Gate pass Date | Gate Pass Date | Yes | This gives the date on which the RM is dispatched. |

| 28. | Transporter Name | Transport Organization Name | Yes | This is the name of the organization which is responsible for transporting the Raw Material. |

| 29. | Transporter GSTN | Transporter Tax ID | Yes | This gives Transporter TAX NO. It’s a unique ID necessary for businesses. |

| 30. | Vehicle No. | Transporter Vehicle Number | Yes | This gives the Transporter Vehicle Number which transports the Raw Material to the Subcontractor. |

| 31. | Courier Name | Courier Agency Name | Yes | This is the Courier Agency Name responsible for delivering the Raw Material to the Subcontractor. |

| 32. | Courier Branch | Courier Agencies Branch Name | Yes | This gives the Courier Agencies Branch which is responsible for delivering the Raw Material. |

| 33. | Courier Date | Date of product dispatch | Yes | This gives the date on which the Raw Material was dispatched. |

| 34. | Docket Number | Vehicle registration number | Yes | This gives the vehicle registration number of the transporting vehicle. |

| 35. | GC / LR Date / Ship Bill Date | Receipt of the lorry | Yes | It is the receipt of the date that specifies the landing date and it’s the receipt that we receive from the transporter. |

| 36. | GC / LR Number / Ship Bill Number | Lorry receipt number | Yes | This gives the lorry receipt from the transporting company. |

| 37. | Packing Date | Date of package | Yes | This tells us the date the Raw Materialwas packaged. |

| 38. | Packing Number | Product package number | Yes | This gives the number allotted for the package. |

| 39. | Number of Packages | Total number of package | Yes | This gives the total number of packages to be delivered. |

| 40. | Weight of Packages | Total weight of the packages | Yes | This gives the total weight of the packages to be delivered. |

ODC is a strong feature and it helps to manage the Inventory thats sent to customer.

Subcontracting ODC is feature that helps to send the RM to Contractors and track the consumption and return of RM back to company.